by Brianna Crandall — March 31, 2021 — Multinational software creator Autodesk just announced the availability of the public beta of Autodesk Tandem, a digital replica solution. Autodesk Tandem brings project data together from its many sources, formats and phases to create a data-rich digital hub that tracks BIM (building information modeling) asset data from design through operations — a “digital twin.”

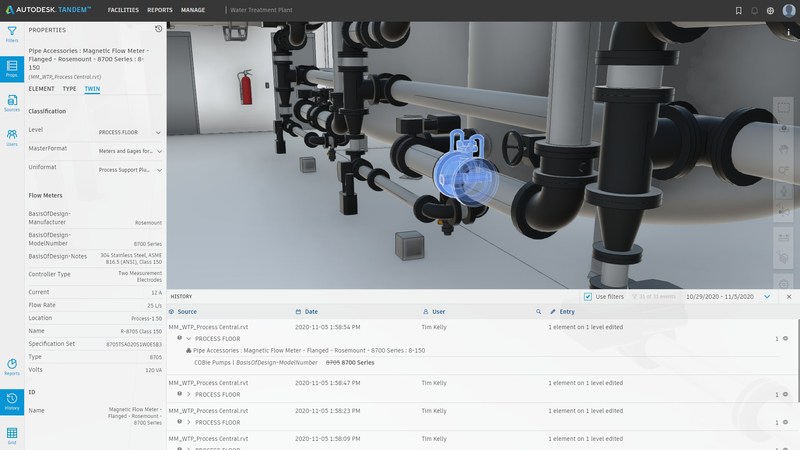

Reviewing asset details for more informed operational decision-making

Autodesk Tandem connects the digital world with the real world, creating an up-to-date reflection of a model’s physical self. This provides unique operational insight into a facility, building, bridge, or any structure, as well as its components, including, for example, the performance of heating and cooling systems, escalators, and electrical systems.

Autodesk Tandem unlocks rich BIM data from building projects, creating a digital twin of all components, systems, and spaces to inform decisions. Image courtesy Autodesk

From design through construction, the project delivery lifecycle of buildings, facilities, bridges, and other physical structures creates an extraordinary amount of data. The data is often disorganized and left unused after handover to owners, developers and operators when the project is completed, points out Autodesk. And building owners want digital data at handover to get the most out of their investment, given nearly 80 percent of an asset’s lifetime value is realized in operations.

Nicolas Mangon, vice president, AEC Business Strategy, Autodesk, remarked:

If the valuable information created during the design through construction phase disappears at handover, owners will lose money. Autodesk Tandem is a purpose-built tool that gives owners and operators greater insight into their completed project, so that they can make informed decisions to improve performance.

With Autodesk Tandem, all project models are brought into a single platform, creating a digital view of projects, along with metadata for each asset. Architects, engineers and contractors can then fully support the digital handover, giving owners a digital twin of the final asset so that they can dive into all design and construction history. Autodesk says this can help break down silos between their respective disciplines and along the entire project lifecycle.

Leveraging nearly 25 years’ leadership in intelligent 3D design and engineering, Autodesk credits building informational modeling (BIM) as one of the foundational components of Autodesk Tandem.

Autodesk sees the platform interfacing with data systems like computerized maintenance and management systems (CMMS) and supervisory control and data acquisition (SCADA) systems to help owners and facilities managers proactively reduce risk and increase resiliency, including tracking open maintenance work orders, assessing the condition of assets, and locating safety equipment.

Marin Pastar, Global Technology leader for Vertical Information Modeling, Jacobs, commented about the product:

We are excited about Autodesk Tandem’s potential to deliver a holistic and usable view of design and construction data as a digital twin for operations. A single source of truth for operations will help reduce the total cost of ownership of projects, and help owners realize the value of BIM long after handover.

In October 2020, Autodesk became a Founding Member of the Digital Twin Consortium, an organization whose members are committed to using digital twins throughout their operations and capturing best practices. Autodesk is also a member of the Open Design Alliance, a non-profit technology consortium that provides support and access to design file formats. Autodesk’s participation in both organizations is motivated by the company’s commitment to openness, working with peers to advance industry, and improving customer experience in the AEC space.

For more information about Autodesk Tandem, visit the company’s website.