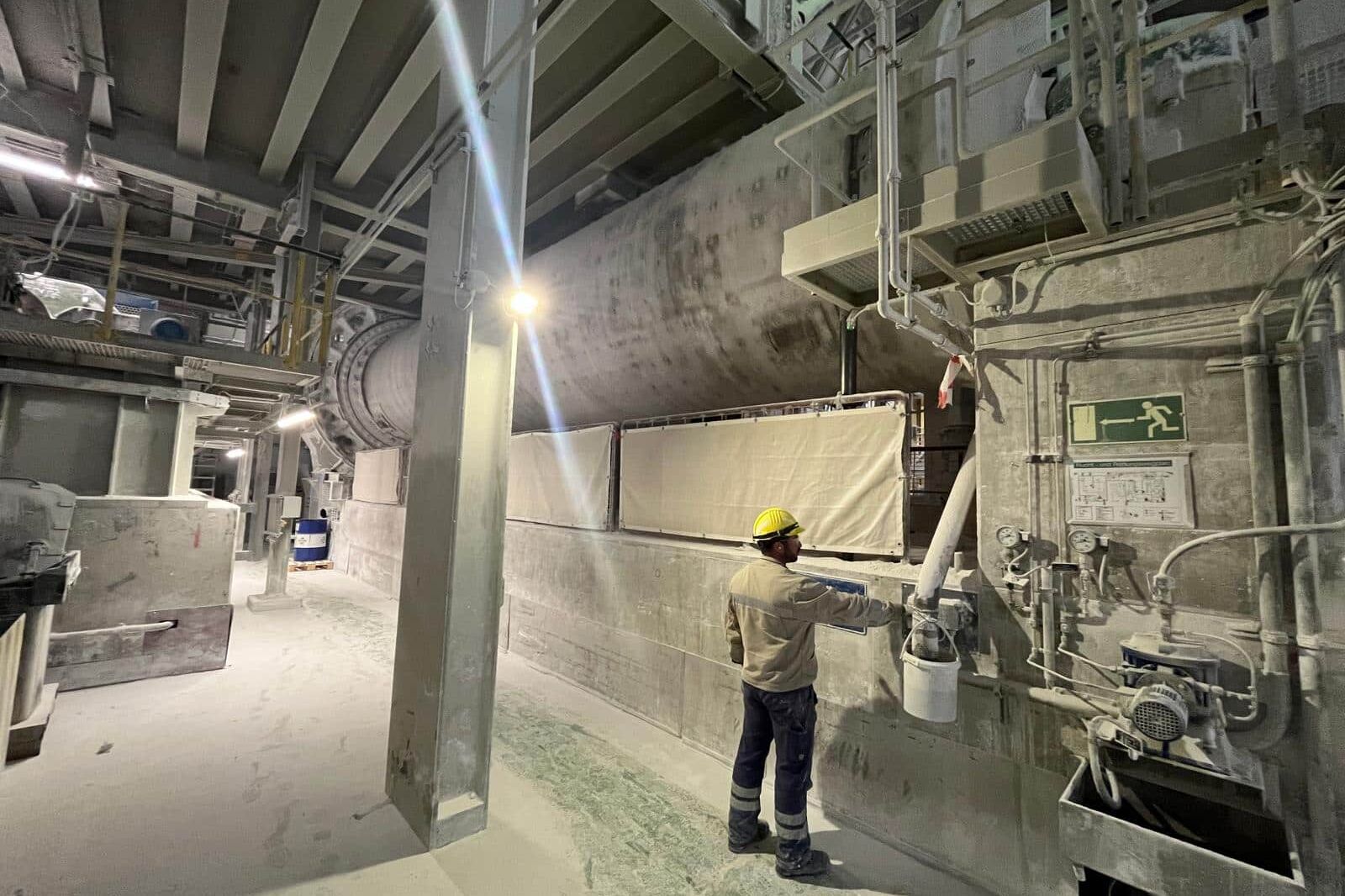

Posted by Janet B. Stroud — October 21, 2024 — Dublin-based HT Materials Science (HTMS) recently announced the successful deployment of Maxwell, a ground-breaking heat transfer fluid for commercial and industrial cooling and heating systems, at an industrial plant. The plant, located in Ludwigshafen, Germany, is owned and operated by Almatis GmbH, a world leader in the development, manufacture and supply of premium alumina (aluminum oxide) and alumina-based products.

Maxwell increased segments of the plant’s cooling system capacity by approximately 20%, which results in an increase in production capacity by an estimated 10% or more per year. The Ludwigshafen plant produces high-quality materials for the refractory, ceramic and polishing industries, and is one of the company’s eight production facilities.

Maxwell increased segments of the plant’s cooling system capacity by approximately 20%, which results in an increase in production capacity by an estimated 10% or more per year. Source: HTMS

The installation was commissioned to demonstrate that Maxwell could reduce the plant’s maintenance requirements and increase production capacity during certain periods of high ambient temperature. This is the second industrial plant in which Maxwell has been used to achieve similar results.

Maxwell is an engineered suspension of sub-micron particles in a base fluid of water or water/glycol (“nanofluid”). Maxwell is a drop-in additive for cooling and heating systems, that works by enhancing heat transfer resulting in reduced energy consumption and increased thermal system capacity.

Almatis’ Ruediger Bastian, global director of Process Technology, stated:

This project is a testament to our pursuit of energy efficiency at every level of our operations. We are always looking for ways to accelerate the energy transition and provide more efficient services that benefit our customers, our stakeholder and the communities in which we operate. This successful project proves the power of international partnership and technological collaboration, and we look forward to working with HTMS to further the application of their technology to advance sustainable cooling solutions.

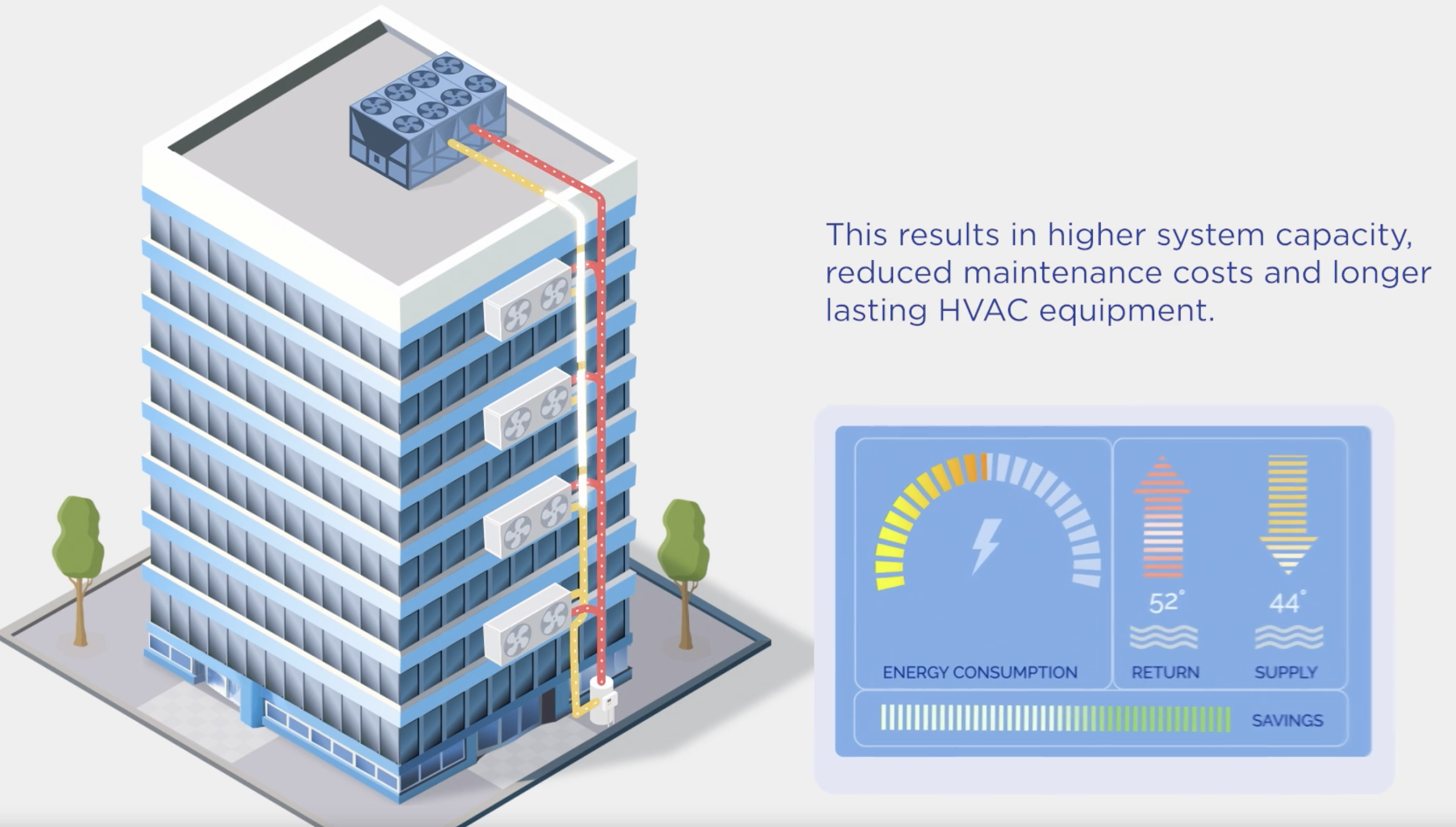

How Maxwell works in a chilled water system

When added to a chilled water loop at a 2% concentration, Maxwell increases the system’s cooling capacity by up to 20%, explains HTMS. This increased cooling capacity allows chillers, fan units, pumps, heat exchangers and other process equipment to operate more efficiently, reducing electrical energy consumption and carbon emissions. Maxwell is a non-toxic, non-corrosive material and fully recoverable and recyclable.

Thomas Grizzetti, CEO of HTMS, remarked:

Thanks to the ease of installation, and use in both new and existing cooling and heating systems, Maxwell can have a material impact on energy usage and the carbon footprint of a broad range of industries and sectors globally. Maxwell is a significant step forward for businesses wishing to drive down energy use, increase system capacity and meet regulated energy efficiency targets increasingly promulgated by governments globally.

HTMS is one of 15 start-ups from across Europe picked to be part of this year’s bigger-than-ever Amazon Sustainability Accelerator. HTMS is among the participants hoping to grow by helping other businesses reduce their impact on the environment.

Find out more about the Maxwell drop-in heat transfer fluid additive at HTMS.