by Brianna Crandall — March 25, 2015—Building owners and managers looking for quick fixes for metal roofing systems that have recently shown a need for some maintenance now have some inexpensive and temporary options. Construction components manufacturer McElroy Metal has developed innovative long-term options that allow metal roofing installers to compete with roofers offering short-term, non-metal systems.

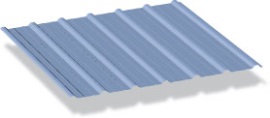

In the company’s quest to provide the most durable system at the lowest possible cost, during the past year McElroy Metal has received patents on two frameless systems to recover the most prevalent metal roof panels in open frame metal buildings: exposed fastener R-Panels and 3-inch tall trapezoidal standing seam. Both systems weigh about 2 pounds per square foot.

“Basically, we use tall clips, fasteners, and insulation,” said Charlie Smith, national recover manager at McElroy Metal. “A major advantage in these systems is not having to add edge or corner framing to meet the wind uplift pressures on the vast majority of existing buildings with 5-feet on-center framing. We also received a patent on an inexpensive natural light strip that can be utilized with either system, so the owner can keep or increase the natural light entering his building with a minimum chance of leaks.”

Metal buildings became a popular and economical method of construction in the 1960s and early 1970s, explains McElroy Metal, but now the R-Panel and trapezoidal standing seam roofs on these buildings are showing their age. Metal roofing manufacturers have been able to offer several options to repair these roofs, everything from the expensive tear-off and re-roof, to the metal-over-metal recover through the use of sub-purlins between the old and new roofing system.

Metal offers the best long-term solution, but price often pushes building owners to look for less expensive options — mostly temporary alternatives to metal. Smith said the first thing owners try is a coating, which is “only a Band-Aid,” not a permanent fix. The next popular alternative that has been winning a large portion of these re-roofing jobs is a single-ply system, which costs about twice as much as a coating and comes with a 15- to 20-year warranty.

“Single-ply may not be the best solution in many of these cases,” Smith said. “There are aesthetic as well as attachment issues. Also, these structures are designed to have water flowing down individual panels. Without individual panels, water tends to flow toward the mid-span of the purlins over time, and this has caused a number of collapses of single-ply recovers over trapezoidal roof panels.

“Now, instead of offering a solution that will be twice as much as the single-ply system, a high-end standing seam roof can be installed for about the same price or as little as 25 percent more.” Smith said that this evens the playing field and provides a roof that will last for many decades.

The 238T Retrofit Clip is reportedly what sets apart the metal recover system from McElroy Metal. The 238T Retrofit Clip works with the company’s symmetrical panel system by sitting between the ribs of the existing roof; it holds the new panel above the ribs of the existing roof while attaching to the purlin below. When installing over an existing R-Panel, the ideal width for the 238T panel is 24 inches, with clips attached to the purlins between every other rib of the R-panel.

This system eliminates the need for sub-framing and saves time and money. The symmetrical panels also allow roofing contractors to start practically anywhere on the roof and work each way, and the symmetrical panels with tall clips add less load to an existing structure. The result is a roof that offers the building owner or manager longevity and less maintenance.