Provided by Universal Fibers — When we invest in high-purchase items such as carpets, fabrics, and other furnishing, we want them to withstand the rigors of daily life. We don’t always appreciate that the secret to long-lasting products often lies in the materials used to make them.

For carpets, textiles, and apparel, durability starts with using nylon 6,6, the best material for the job. Since its early use in World War II parachutes, nylon 6,6 has been known for its durability and strength, even when spun into thin, lightweight fibers.

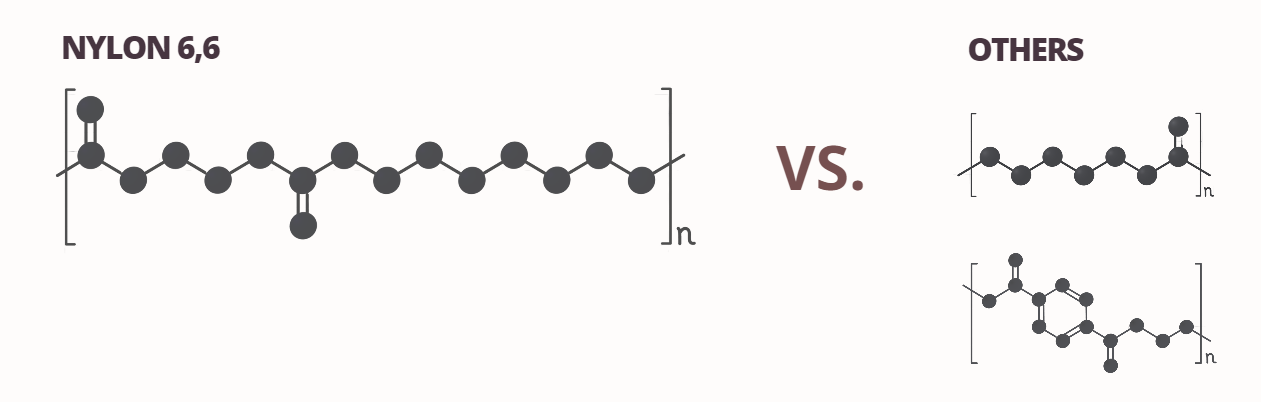

Today, nylon 6,6 can often be confused with other, less sturdy fibers that tend to perform poorly over time. These less durable materials often lead to disappointment and eventually end up in landfills.

The strength of nylon 6,6 comes from two key factors: how well it holds up under stress (tenacity) and how well it resists wear (abrasion).

Tenacity: Strength you can count on

Nylon 6,6 is stronger than other fibers, meaning it tears less easily and holds its shape longer. This strength offers significant advantages in many applications, particularly textiles and carpets. The increased resistance to tearing and stretching makes garments more durable and long-lasting, even when subjected to regular wear and tear. For carpets, this means better resistance to foot traffic and flattening, keeping them looking newer for longer.

Test results confirm that nylon 6,6 can withstand 15% more force to break than a similar polyester fiber of the same denier or fiber weight. The enhanced tenacity of nylon 6,6 allows for the production of thinner, lighter fabrics without compromising strength, offering flexibility in design while ensuring the material’s longevity. This characteristic makes nylon 6,6 an ideal choice for high-performance and heavy-duty applications, where the balance between weight and strength is crucial.

Abrasion resistance: Standing up to wear and tear

Another key property of nylon 6,6’s durability is its abrasion resistance. This is a material’s ability to handle more friction without wearing out, similar to how the surface of a rug or carpet might suffer from wear and tear over time. This characteristic is essential for many carpets, as they are subject to constant foot traffic and friction in high-traffic areas. Nylon 6,6 excels in this area, making it an exceptional choice for carpets.

Abrasion is tested with machinery that simulates wear and matting by rubbing the material through several cycles before it wears thin, crushes the fibers, or develops holes in the material. Nylon 6,6 demonstrates superior performance in each of these tests, with a typical 6,6 material enduring around 40,000 cycles before showing signs of wear. In contrast, an alternative, inferior fiber can generally withstand only about 20,000 cycles in the same testing.

Conclusion: Performance starts with selecting the right material

Durability is a key consideration when specifying, as it affects the longevity and appearance of the finished product — and that really comes down to the material selected.

For high-traffic areas in commercial, educational, or hospitality settings, carpets made with nylon 6,6 can be specified with confidence. Compared to their counterparts, nylon 6,6 carpets can withstand years of constant foot traffic, frequent furniture and equipment movement, and regular cleaning regimes, all while retaining their appearance.

Learn more about nylon 6,6 and contact a Universal Fibers representative here.

Learn more about nylon 6,6 and contact a Universal Fibers representative here.