Although it didn’t take long for the hospital’s emergency-power to switch on, there was a big problem with the HVAC system: air had resumed circulating through the vents, but it was no longer being cooled. Staff soon learned that the facility’s chillers were not connected to the emergency power circuits.

Although it didn’t take long for the hospital’s emergency-power to switch on, there was a big problem with the HVAC system: air had resumed circulating through the vents, but it was no longer being cooled. Staff soon learned that the facility’s chillers were not connected to the emergency power circuits.

On a summer evening in 2019, a massive power outage struck the epicenter of New York City’s tourist district. Subway lines screeched to a halt, Times Square’s glittering lights went black, and operations at a large hospital came to a standstill.

Without proper temperature control, the hospital wouldn’t be able to maintain a healthy environment for patients, and staff had no choice but to plan an evacuation of patients to other hospital facilities in the area. Thankfully, the city’s main power grid turned back on, and the evacuation was narrowly avoided. Imagine, however, the monumental undertaking it would’ve been to move hundreds, if not thousands, of patients? And all because staff hadn’t received an

alert that the facility’s chillers weren’t connected until there was a crisis.

What happened at the hospital never should’ve happened. Safe, resilient, and efficient mission-critical facilities require operational transparency to ensure that everything from emergency-power systems, hot-water temperatures, steam availability, and differential pressures are meeting requirements. To gain this transparency, facilities must first achieve real-time

What happened at the hospital never should’ve happened. Safe, resilient, and efficient mission-critical facilities require operational transparency to ensure that everything from emergency-power systems, hot-water temperatures, steam availability, and differential pressures are meeting requirements. To gain this transparency, facilities must first achieve real-time

situational awareness of all their assets.

This white paper will help facility managers gain greater literacy about situational awareness by discussing how to:

- Achieve operational transparency via a real-time situational awareness platform.

- Attain a common operating picture of a facilities environment.

- Implement advanced analytics and a central data infrastructure and adhere to the data-driven concepts these things enable (fault detection, condition-based maintenance, and predictive modeling).

Let’s get started down the path toward increasing situational awareness.

A road map for safer, more efficient facilities

A road map for safer, more efficient facilities

Thirty years ago, backup generators and reduced services might’ve been all a facility needed to keep mission-critical systems functioning during a power grid outage or other emergency. Technological advancements have changed the demands of facility operations. The demands include increased energy consumption from our drive to automation and digital platforms, and finer tolerances for health and safety systems, and all while balancing reliability, availability, and the new demand of sustainability.

Those changes alone would be enough of a challenge, but managing them has become more complicated as we juggle even newer demands, such as the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), and automation systems. Facilities require more assets, data, and power than ever before to meet the demand required by the connectivity of all these systems new and old, plus the tighter tolerances mandated by updating building codes and health and safety systems.

Times have changed, and so have the needs of facilities. Unfortunately, many managers don’t have a clear enough view of mission-critical systems to be able to prevent and predict asset and system failures. Therefore, they must prioritize gaining situational awareness of all their assets,

including the ones that aren’t regularly used.

Gaining situational awareness

We all know that we need situational awareness (SA), but what exactly does the term mean? Quite simply, having SA means that we have an understanding of what is happening around us, while a lack of it means we don’t know what’s going on.

In facilities, the definition of the term is a little more complicated. Gaining SA requires

moving through three different states: perception, comprehension, and projection. The awareness comes by first perceiving events or elements with respect to time and space, comprehending their meaning, and then projecting their status into the future. In a facilities environment, perceiving, comprehending, and projecting the status of events translates to real-time, automated monitoring of critical systems.

Gaining SA requires a comprehensive understanding of a facilities operation that

can only be achieved through the integration of disparate operational and legacy systems.

It acts as a tool to help decision makers understand the ever-changing environments within mission-critical facilities such as airports and air traffic control, hospitals, and utilities enterprises, and it offers predictive, rather than reactive, maintenance.

The relationship between situational awareness and operational intelligence

Replete with powerful sensors, countless moving parts, and a variety of disparate operational systems, 21st-century facilities create enormous amounts of data. Operational intelligence (OI) is the process of receiving, reviewing, and evaluating all this data, and it offers real-time business analytics that help streamline operations by providing transparency and insights into data.

Layered over situational awareness, OI uncovers correlations and relationships that highlight areas where operational and business improvements can be made and points out where capabilities exist. The conjoining of SA and OI leads to situational understanding, which drives financial and operational value.

Goals and challenges in facilities

Operations data can deliver a holistic view of assets and processes by using interconnected but disparate systems at the central utility plant, as well as individual building automation systems, metering systems, health and safety systems, and other mission-critical data sources. As a result, making improvements to real-time data infrastructure positively impacts facilities management.

Operations data can deliver a holistic view of assets and processes by using interconnected but disparate systems at the central utility plant, as well as individual building automation systems, metering systems, health and safety systems, and other mission-critical data sources. As a result, making improvements to real-time data infrastructure positively impacts facilities management.

Situational awareness and operational intelligence can be applied to all facilities, but they are especially relevant for missioncritical facilities with unique requirements, processes, and visions. The mission of a corporate campus, for example, is to support core business operations, while the mission of a hospital is to save lives.

All facilities may have different missions and needs, but they do share some operational

goals. On the following page, we’ll outline four key goals before we discuss some of the

challenges preventing facilities from attaining these targets

Washington grinds to a halt

In April 2015, Washington, D.C., came to a screeching halt because of the fragility of its power grid. In an instant, 49,000 students, faculty, and staff at the University of Maryland at College Park were thrust into darkness.

Even in the worst of situations, universities should be able to provide adequate power for their campuses, but the grid failure at the University of Maryland at College Park showed that because of the increased interconnected nature of today’s power grids, more resilient solutions must be implemented to protect the health and safety of the community.

Although the power failure in 2015 showed a lack of integrity in its power grid, the university subsequently began to increase the situational awareness of its campus so that it could respond to any future power grid failure in real time.

Four goals drive operation of mission-critical facilities

The primary objective of every mission-critical facility is to operate safely, reliably, and efficiently at its optimal design capacity. This objective can be achieved by meeting the following four goals:

- Safety

The top goal for facilities is to provide safe, compliant environments for the people who

use them. Safety impacts all areas of a facility, from electrical generators to specific conditions inside every room and across entire enterprises. When mission-critical systems fail, there can be catastrophic consequences.For example, as we detailed in the earlier hospital scenario, even a single failed sensor

or asset can put critical patients at risk and may lead to an emergency evacuation. - Resiliency

Facility staff are responsible for ensuring that a safe environment is maintained in all circumstances. Today’s facilities, however, are vast, complicated networks of disparate

systems and assets that produce endless data streams. For example, a large hospital complex that has 200,000 streams of data may actually produce over 5 billion points of data in 24 hours. Humans cannot visualize all this data, let alone analyze and prioritize the meaning of it without real-time analytical software and support. - Efficiency

There’s a constant pressure in facilities to reduce costs and improve outcomes. Facilities have to do more with less. Small, obvious changes to facility management processes— such as having sensors that automatically urn lights on and off—can make big impacts on business. It’s a bigger but necessary job to diagnose underlying inefficiencies and then retrofit facilities with upgraded systems and solutions. Automation systems focus on performance against set points and have no knowledge of efficiency or sustainability. - Reporting requirements

Facilities must be compliant in a wide range of areas. Every country, region, city, and industry adds a layer of complexity to operational compliance. Health care facilities, for example, must follow reporting regulations related to temperature, humidity, pressure, ventilation, and air filtration in order to receive accreditation, while a central utility plant whose activities may yield environmental impacts must meet reporting regulations set by the EPA. There is a constant and growing demand for all commercial facilities to report energy consumption to either EnergyStar or to state or city regulators.

Challenges

Challenges

It’s vital that facilities management recognize challenges that relate to the nature of the operation, its maintenance posture, and the limited access to its facility’s data. These challenges include:

- Energy-intensive 24/7 operation:

Facilities spent billions of dollars on energy, yet many facility managers approach energy

as merely a cost to be managed. There’s huge potential for improvement in energy-intensive industries such as food processing, pulp and paper, metals, and oil refining sectors, but all industries should examine their energy usage. A recent U.S. Department of Energy study, for example, showed that in 2018, health care facilities alone spent almost $10 billion on annual energy costs. - Reactive maintenance posture:

Constraints in staffing, funding, or both of these things in tandem forces facilities into a

mode of operation where preventative, rather than predictive, maintenance dominates the

workflow. This means that facilities are always playing catch-up, and they can never get

ahead of issues. - Limited insights (or a lack of a common operating feature):

Facilities contain multiple disparate legacy systems, each with its own processes,

reporting, analytics, and login information. With so many systems, it’s hard to get a

handle on what’s happening in a facility, as management can’t see everything

in each system at the same time. This makes it impossible to evaluate an entire

facility’s systems.

Overcoming challenges

The operational and maintenance challenges faced by facilities point to a need for a data-infrastructure solution that leads to greater situational awareness and operational intelligence. Only then can the sort of transparent, holistic insights that allow facility managers to make informed decisions for their facilities and enterprises be gathered.

Integrating disparate systems for awareness and intelligence

Facilities have many typical systems, including building automation, maintenance management, lighting, diagnostic, critical power, security/fire/life safety, utility, geospatial, and SCADA, and automation systems that run HVAC. Each of these disparate systems produces its own data streams, and the systems are almost never integrated.

The value of the data in stand-alone systems can be increased through integration. Across

any facility, for example, there are a number of air filters that need to be changed. In

traditional facilities, these filters are changed on a time-based schedule. This often results

in air filters either being replaced when they aren’t dirty, or getting clogged because they

haven’t been changed in time. Integrating a facility’s automation system and its maintenance-management system solves these inefficiencies. The automation system’s powerful sensors monitor pressure-drop processes across filters in real time, and produce a work ticket or service request in the facility’s maintenance-management system when it’s time for that filter to be changed. In other words, the facility leverages data collected by the automation system and

connects it to the maintenance-management system so that facility managers can take action.

While the number of stand-alone systems and data can feel overwhelming, integration can offer more access to data, real-time information, and improved operational insights.

The power of central data-center infrastructure

While traditional facility-infrastructure management keeps information technology (IT) and building-facilities functions separate, a central data-center infrastructure solution like OSIsoft’s operational-intelligence PI System allows users to integrate IT and operational technology (OT) data from any number of stand-alone solutions into one common database.

The right analytics approach for the job

The right analytics approach for the job

Every facility is unique. Therefore, facility managers must beware of third-party vendors peddling flashy one-size-fits-all data-management solutions. Most of these vendors say that their platform can handle analytics, but they assume that facilities will provide an analytics-ready data set. This simply isn’t the case. Instead, facilities must implement data-management

solutions that can truly provide analytics.

This can be done using a central data-center infrastructure, which in turn enables several

data-driven concepts such as fault detection and diagnostics, condition-based maintenance,

and machine learning, which can mitigate risk and increase a facility’s efficiency and resilience.

These different analytics approaches can be used as needed by facilities:

Fault detection and diagnostics (FDD)

Because the integrity of mission-critical assets is dependent on all its disparate parts functioning, potential problems in the performance of a facility’s equipment and

systems must be identified before failures occur. FDD relies on central data-center

infrastructure that gathers time-stamped data for analysis, but it also applies business

rules to real-time asset data. It is used with HVAC systems and equipment to help

engineers determine when assets aren’t performing optimally, and it then helps

facility management decide how and when to fix those assets.

Condition-based maintenance (CBM

CMB increases situational awareness by harnessing the power of the IoT and nextgeneration technologies like artificial intelligence like (AI) to find hidden problems in specific building systems. CBM takes the real-time operations data collected by open data infrastructure at large facilities like central utility plants and then predicts and prevents equipment downtime and improves building-system effectiveness.

Machine learning (ML)

ML describes how various disparate building systems can improve the performance of tasks

even if they haven’t been preprogrammed with information. Using computational learning theory and pattern recognition, ML uses various algorithms to analyze data collected by a central data-center infrastructure. Different algorithms can be used to analyze different tasks or divide tasks into distinct, measurable steps.

Critical power readiness

The reliability of mission-critical facilities is paramount to protect people and business

assets. Critical power readiness is an approach that uses data collected by a central datacenter infrastructure to examine critical operations. This approach provides feedback about gaps within these operations, allowing facility managers to develop customized solutions such as uninterruptible power systems and backup readiness. Obtaining critical power readiness is essential for facilities wanting to control risk factors that are typically deemed uncontrollable, such as power outages and issues that arise during natural disasters.

Continuous monitoring

IoT technology has allowed powerful sensors to be directly embedded into various building systems. These sensors gather data 24 hours a day, and can help monitor temperature, pressure, the presence of toxic pollutants, and humidity even when employees aren’t present. Around-the-clock monitoring ensures that a facility’s assets perform as they ought to at all times.

From campus to component: Why all parts of a facility must be analyzed

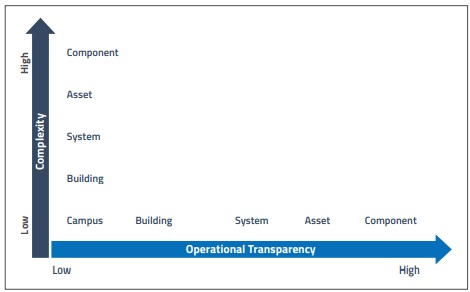

Trade-offs exist when you try to increase situational awareness across all parts of a facility, from the building itself to the smallest of components. Yet to improve situational awareness, every one of a facility’s moving parts, assets, and components must be analyzed.

The complexity of analysis, for example, for utility-level information at a campus or a

building is low. Managers might benchmark these sorts of facilities using key metrics such

as energy-use intensity (EUI) or an energy-cost index. The amount of operational transparency

that can be gathered from these analyses is also quite low, making it difficult to get significant insights about specific systems. At system, asset, and component level, the opposite holds true: the insights that can be gathered are tremendous, but the complexity of the analysis and assessment also increases, meaning facility managers must worry more about data storage and processing. If a campus, for example, is going to glean insights about every one of its dampers and fans, the question arises of what to do with all this data. The following applications take a look at two examples of how these concerns are addressed, starting at campus level and ending with individual components.

Campus electrical generation: Moving from reactive to predictive maintenance

Campus electrical generation: Moving from reactive to predictive maintenance

A large campus on the East Coast with over 100 buildings and a variety of critical spaces wanted to create a common operating picture of its utility consumption. To do this, the campus created a dashboard that segmented the visualization of data. One portion of the dashboard focused solely on electricity, showing generating assets and imported electricity from the grid. Other portions of the dashboard visualized chilled water generation and steam generation.

Before this dashboard was created, the information it showed lived in various stand-alone systems such as the facility’s automation and a utility-focused SCADA system. Unfortunately, this means that facility management didn’t have one place to go to visualize all their systems in real time. By the time they received the information, it was no longer useful, as it was no longer in real time. Once the integration of systems occurred and real-time data was collected and visualized in a single dashboard, situational awareness increased. The value of this transparency and continuous insights about utility consumption has led to energy costs being minimized.

When the dashboard is expanded to include weather-forecast data—showing, for example, that a heat wave will happen in a few days —facility management can increase its ice storage and provide advanced warning to staff about predicted changes in energy use. The key takeaway is that by implementing a single dashboard, the campus could get ahead of outages and other issues caused by weather events by moving from reactive to predictive maintenance.

Safe, resilient facilities require strong situational awareness, the use of operational intelligence,

and analytics-ready, time-stamped data to drive decision-making. By taking a systemic

approach that prioritizes systems integration and targeted analytics, facilities can undergo

holistic transformation, reducing risk, improving safety, and decreasing operating costs.

About OSIsoft

The world’s most essential and complex industries rely on OSIsoft to manage the lifeblood of the industrial enterprise: operations data.

OSIsoft is a pioneer in data-infrastructure strategy and a global leader in operations data management software. The company brings over 40 years of experience helping industrial organizations meet next-generation demands for efficiency, reliability, security, sustainability, and resilience.

OSIsoft’s market-leading PI System is the proven system of record for operations data in essential sectors such as power generation and utilities, water, oil and gas, mining, metals, manufacturing, pharmaceutical, facilities, transportation, food and beverage, and more. Every day, industrial professionals in 146 countries rely on the PI System to improve performance, protect health and safety, keep the lights on, and make the world run more smoothly.

Learn why two-thirds of Fortune 500 industrial organizations choose PI System

at www.osisoft.com.

Corporate Headquarters:

1600 Alvarado Street

San Leandro, CA 94577, USA

Contact: +1 510.297.5800